Breakdown Maintenance Case Study

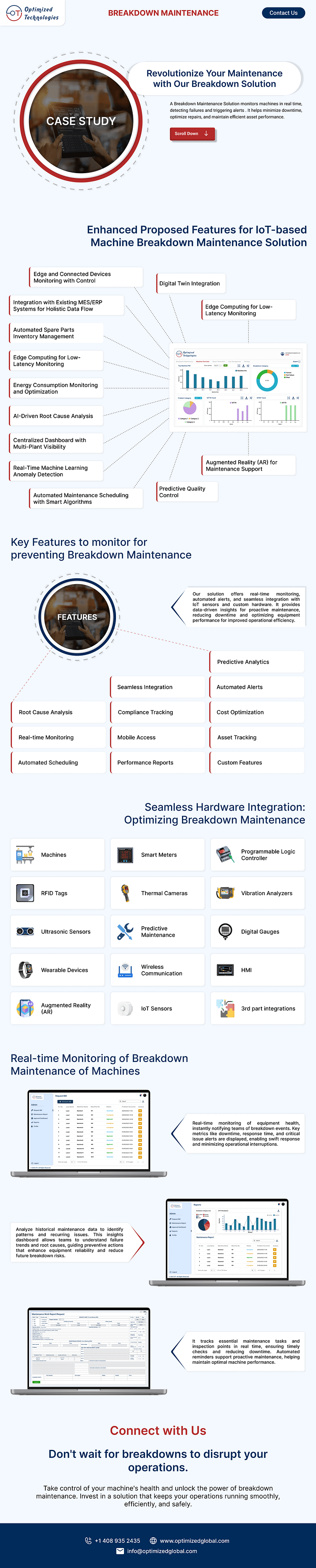

Our Breakdown Maintenance Solution provides a proactive approach to machine management by leveraging real-time monitoring, preventive maintenance, and automated alerts. Designed to minimize downtime, it quickly identifies and addresses failures, ensuring optimal asset performance. Seamlessly integrating advanced sensors, smart meters, IoT devices, and custom hardware including temperature and pressure sensors, ultrasonic sensors, GPS trackers, and vibration monitors, our solution delivers data-driven insights. It enables efficient maintenance planning, enhances operational efficiency, and supports business continuity.

Key features include real-time alerts, breakdown analytics, comprehensive check-sheet maintenance, customizable dashboards, and easy access to software at your fingertips. The solution also supports digital checklists, maintenance scheduling, automated reporting, and detailed performance analysis to ensure accurate documentation and streamlined maintenance workflows.

If you're looking to optimize your equipment maintenance and minimize downtime, our Breakdown Maintenance Solution is the perfect fit. Get in touch with us today to learn how we can help you enhance operational efficiency, streamline maintenance workflows, and ensure business continuity. Contact us for a demo or to discuss how our solution can be tailored to meet your specific needs.

Connect with us to know more!

Email: support@optimizedglobal.com

Website: https://optimizedglobal.com/

LinkedIn: https://www.linkedin.com/company/optimizedtechnologies-inc/